On November 25th, 2020, US PP Compact Hydrogen Generator Project representatives had the Factory Acceptance in ALLY’s assembly factory for the 200 kg/d integrated hydrogen generator via natural gas who has carried on the full capacity. Subsequently, it will be shipped to Brookhaven, Mississippi, US. The project's factory acceptance, marks that ALLY HI-TECH’s hydrogen generator via natural gas officially enters the U.S. market.

During the acceptance process, the project owner’s representatives listened to the reporting regarding the project implementation management from ALLY’s chairman, Yeqin Wang (Hunter), the project manager, Gaorong Hu (Robb), and ALLY’s Deputy General Manager, Jianhua Gao. They had checked the on-site hydrogen analysis report, the project data, the instrument and equipment configuration and the project running condition at full load.

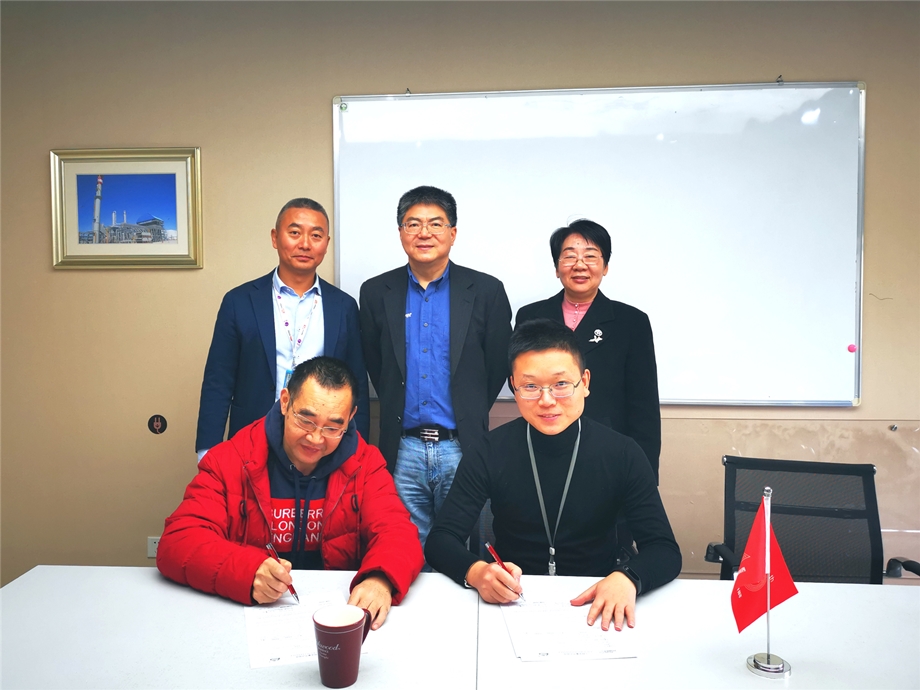

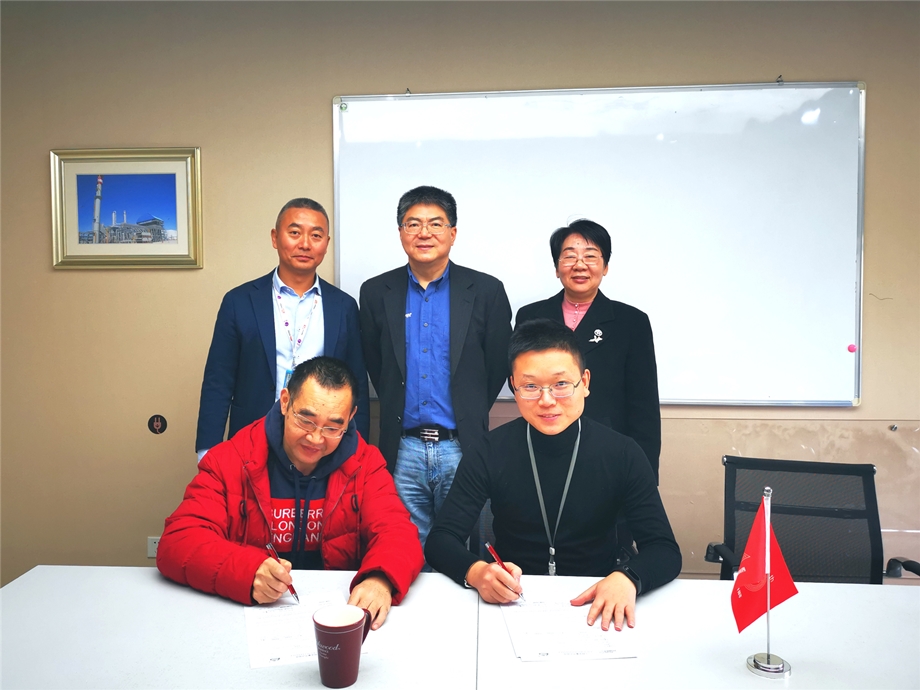

The project owner’s representatives gave high evaluation to the completion of the project! The data provided by ALLY’s project team are complete; the implementation of the project is scientific; the generator on site is consistent with the drawings; the data results are satisfactory. Thus, the generator is in line with the shipping requirements, and both parties signed the Factory Acceptance Report.

Plug Power is a US market-listed leading company in the field of hydrogen energy, an international leading provider of clean hydrogen and zero-emission fuel cell solutions that are both cost-effective and reliable. The project is based in Brookhaven, Mississippi, and provides a hydrogen refueling service for Wal-Mart's supermarket logistics. According to the representatives of Plug Power, the company is the largest client in the global liquid hydrogen market. It needs to be equipped with multiple hydrogen sources in order to ensure the long-term stable operation of the hydrogen refueling station.

At present, the main way to obtain hydrogen around the world is to make hydrogen from natural gas. It is also the most feasible and reasonable way at present According to the DATA of the US Department of Energy, 95% of the hydrogen in the US produced by natural gas, and about 80% of the hydrogen in the world comes from the same technical route.

For 200kg/d Compact hydrogen generator from natural gas, ALLY has adopted the most advanced technology with the total footprint less than 100 square meters, which includes compression unit, desulfurization unit, reforming unit, hydrogen purification unit, DMW system, instrument air system, cooling water system, power distribution unit and automatic control device. The generator had been running for full capacity for more than 7 days. The natural gas consumption is lower than 0.45 Nm3/Nm3-H2, and various technical indexes had met the design requirements, especially the hydrogen purity met the standard of fuel cell. Back in 2008, ALLY HI-TECH had provided integrated Hydrogen generator for the Beijing Olympic Games, which was the first domestic on-site hydrogen refueling station demonstration project.

The generator uses one button to start and stop. It achieves remote diagnosis and control to ensure the normal operation and maintenance of plant. The device is designed and manufactured in strict accordance with the US standards and specifications, which is the most demanding hydrogen production device in more than 600 sets of hydrogen production devices built by ALLY. The project team carefully studied the relevant technical standards and specifications of the US. With their "rigorousness, rigor and strictness", various technical requirements of the device have finally been realized. ALLY adheres to the principle of focusing on quality, and its serious and responsible attitude and practical actions have proved its leading level of technology, teamwork spirit and sense of mission.

We certainly believe that the ALLY’s tomorrow will be better, and the hydrogen energy development will be better! Green ecology, hydrogen dynamic future is coming.

research and development results

research and development results