-

Home

-

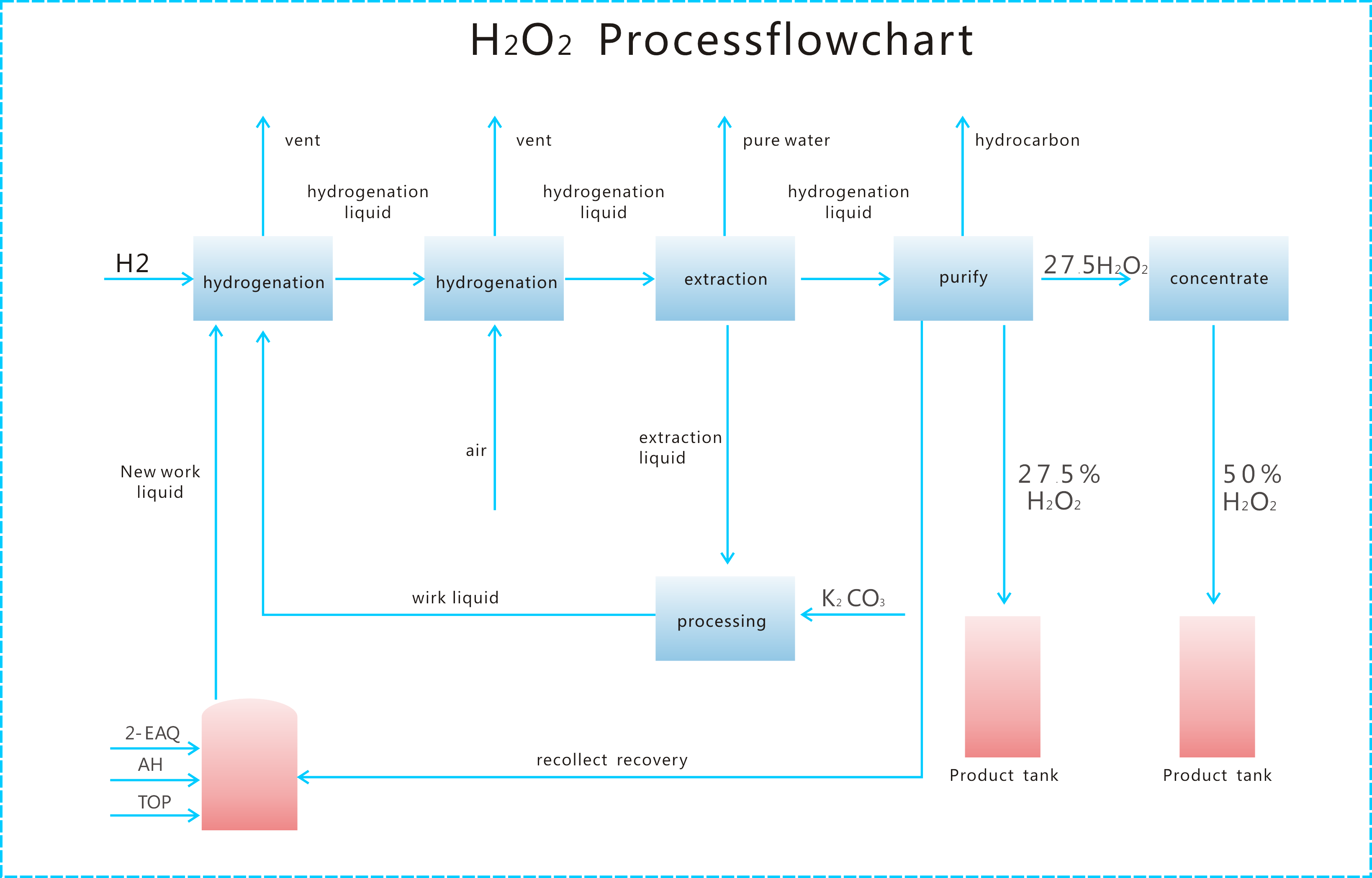

hydrogen energy application

-

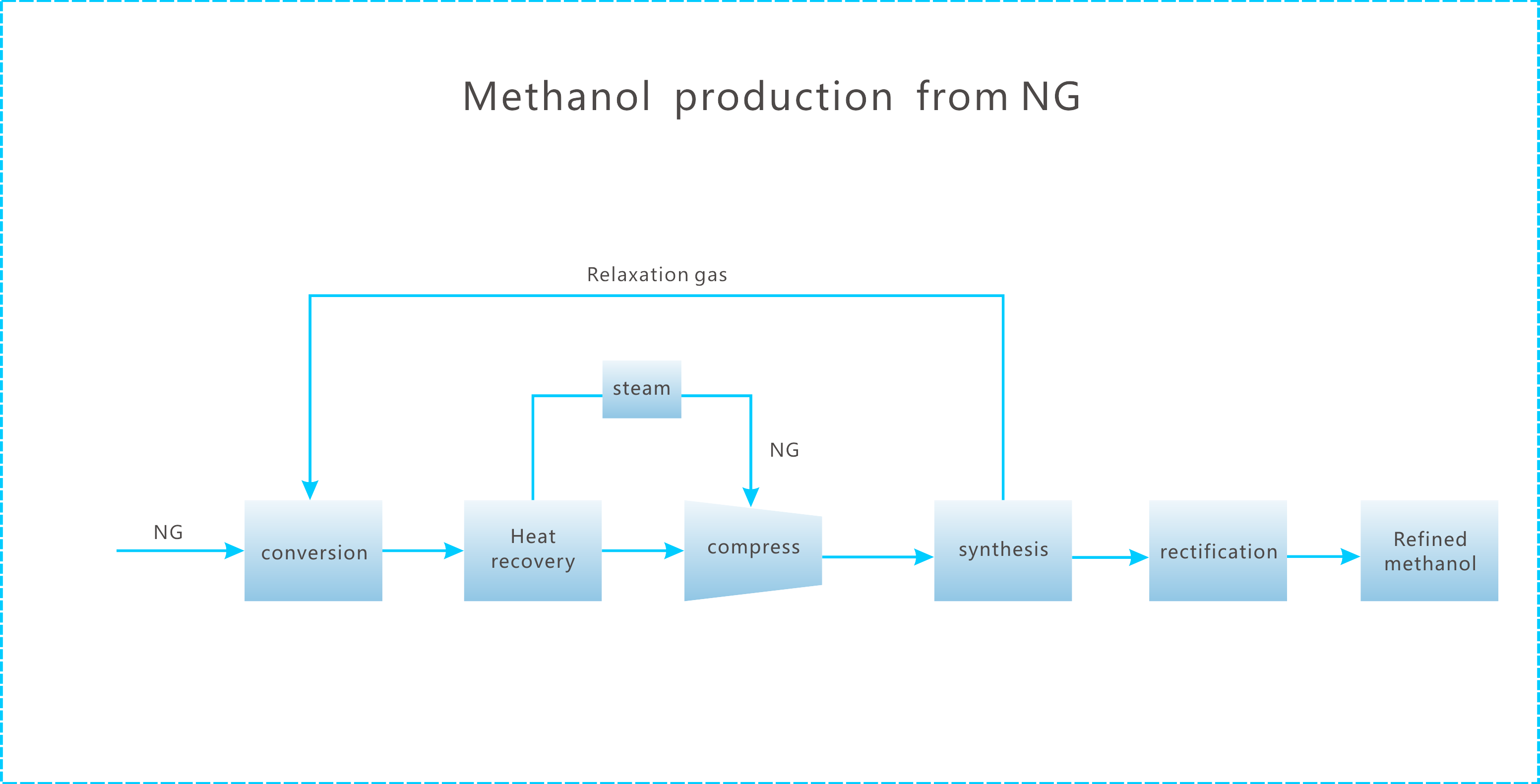

hydrogen production equipment

hydrogen production equipment

Hydrogen generator by Electrolysis Hydrogen plant by methanol reforming Hydrogen plant by SMR from natural gas Hydrogen recovery plant by PSA technology -

other products

-

cooperation cases

-

company introduction

research and development results

research and development results -

human resources